Forming Fabrics

What is Forming Fabrics?

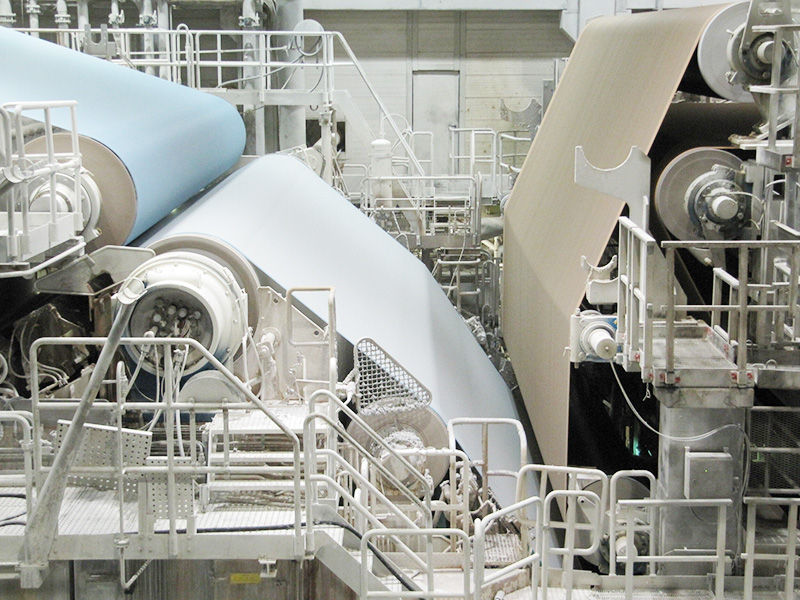

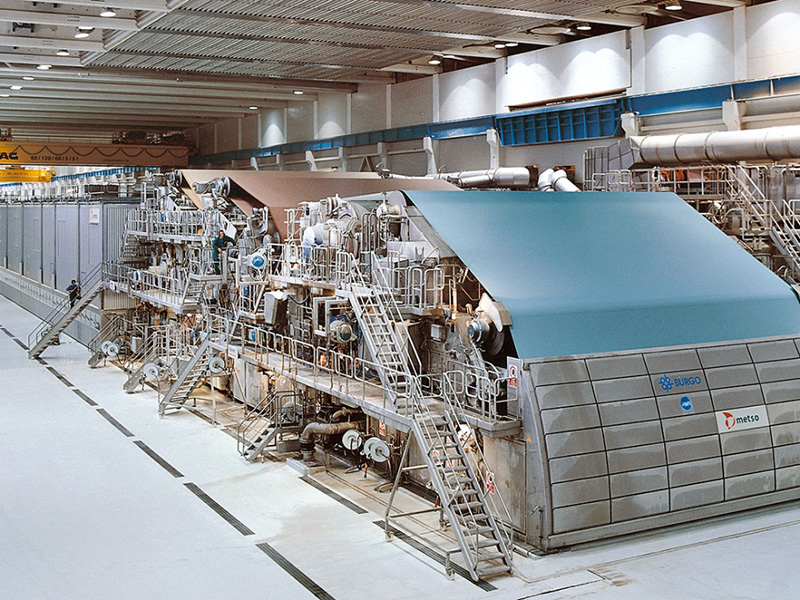

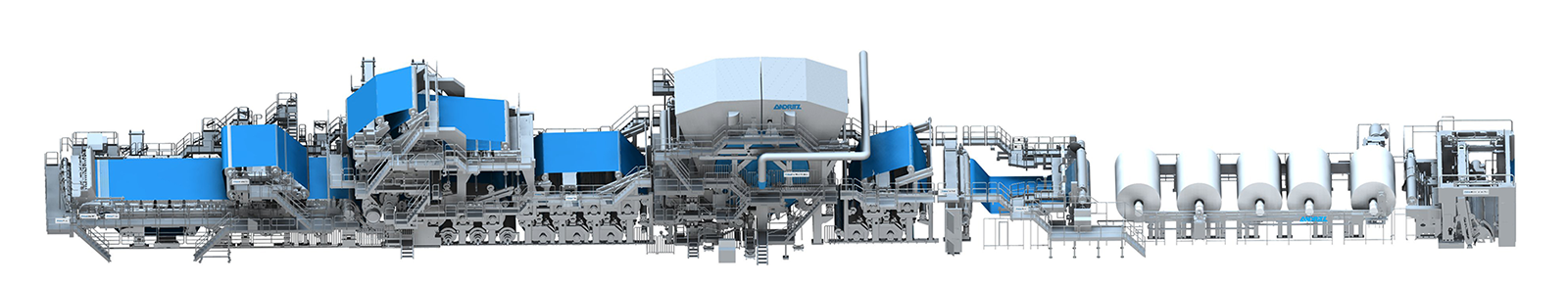

The forming fabrics of paper machine clothing (PMC) are playing a crucial role to dewater the pulp and form the paper sheet, support the sheet as it formed and carry to the next pressing section during the paper production. It's composed of one or two endless fabric loops.

A properly designed constructed and maintained forming fabrics will help the former produce a sheet that meets end-products specification at an acceptable production rate. In addition to excellent fiber support, efficient dewatering property, make the smooth surface of the sheet, the forming fabrics also has good running stability and abrasion-resistant capacity.

Forming Fabrics Category

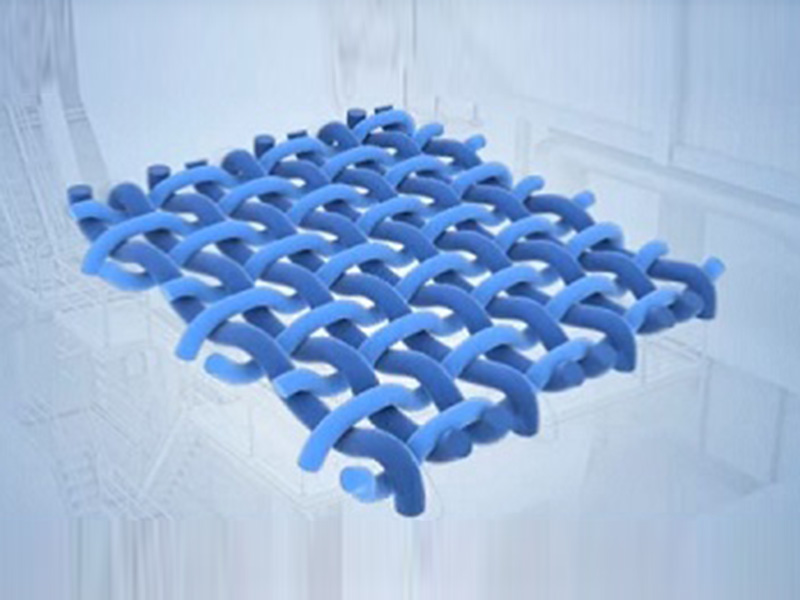

Forming fabrics for the paper machine are made by weaving together yarns oriented in the machine direction (MD) and cross-machine direction (CD). There are many different weave patterns but they can be grouped into four general categories or styles based on the number of CD yarn layers.

The four fabric styles are:

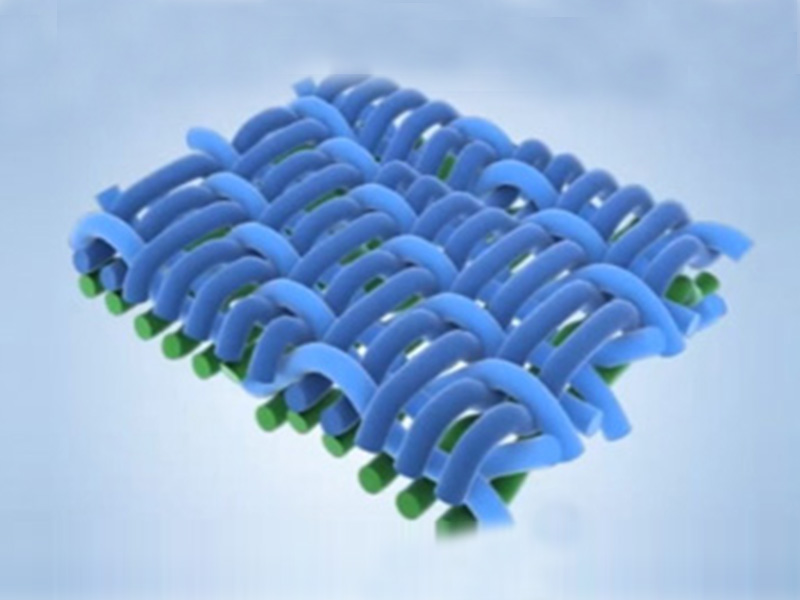

The single layer polyester forming fabrics is the simplest forming net, It includes four different forms:

1. 2-shed (one up and one down) : The design is mainly used in sewage treatment plants, sludge dewatering machines, etc.

2. 3-shed (one up two down): Mainly used for sludge dewatering machine, washing machine and bleaching machine.

3. 4-shed (one up and three down) : Mainly used for various paper machines.

4. 5-shed (one up and four down) : Mainly used to produce all kinds of kraft paper, tissue paper, writing paper, printing paper, etc.

1.Simple structure of single layer forming network, good dewatering and good air permeability.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Applications

1.Pulping, pulp washers.

2.Writing papers, printing papers, kraft papers, newsprint papers, corrugated paper,tissue papers and so on.

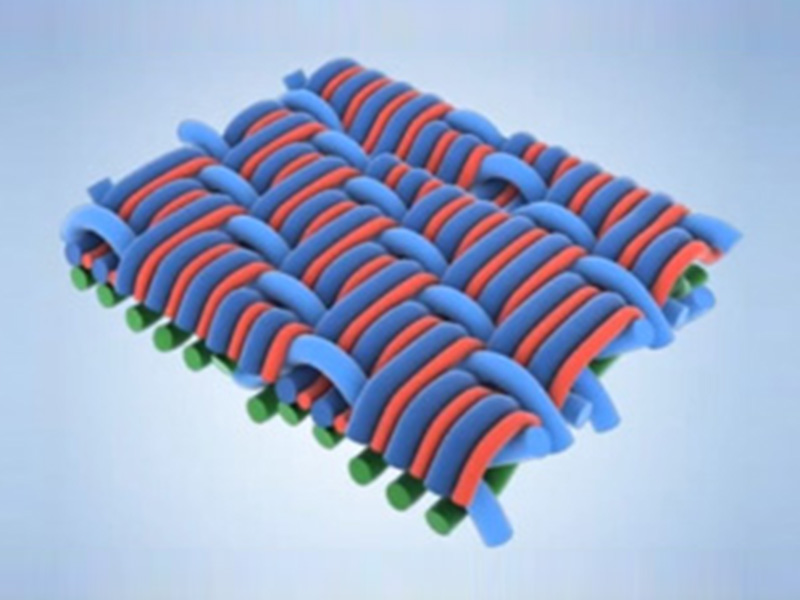

Double-layers forming fabrics, two sets of CD yarns stacked on top of each other woven together with one set of MD yarns, to enhance the abrasion resistance property and fiber support.

Double layer forming fabrics is common polyester forming conveyor belt for paper making manufacturer, highly unique design structure can avoid Longitudinal load and Horizontal wrinkling, double layer forming wire will increase the mesh stable and drainage,improve mesh fabrics work life.

With the increase in the speed of the paper machine and the increase in the width of the polyester forming fabric, the double layer forming fabric is indeed an overhead.

The 8-shed double-layer forming wire includes a group of longitudinal fiber healds and two sets of transverse fiber heals, which allows the small fibers to stay on the top layer, and the use of thicker fiber weaving at the bottom helps to obtain better sheet forming characteristics, this double-layer design will gain more stability in size than a single-layered mesh design.

The 16-shed double-layer forming mesh creates a new concept that can increase the life of the net cloth without affecting the quality of the paper, after the life of the bottom material of the net is increased, the life of the entire net cloth is usually improved, usually 16-shed forming fabrics are used for the production of paper machines and coarse kraft paper machines, double mesh screens can be from 60/cm to 32/cm.

1.High dimensional stability, unique weaving structure can resist longitudinal load and horizontal wrinkling.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Application

1.Paperboard.

2.Newsprint,writing paper.

3.Tissue paper.

4.printing paper,kraft paper

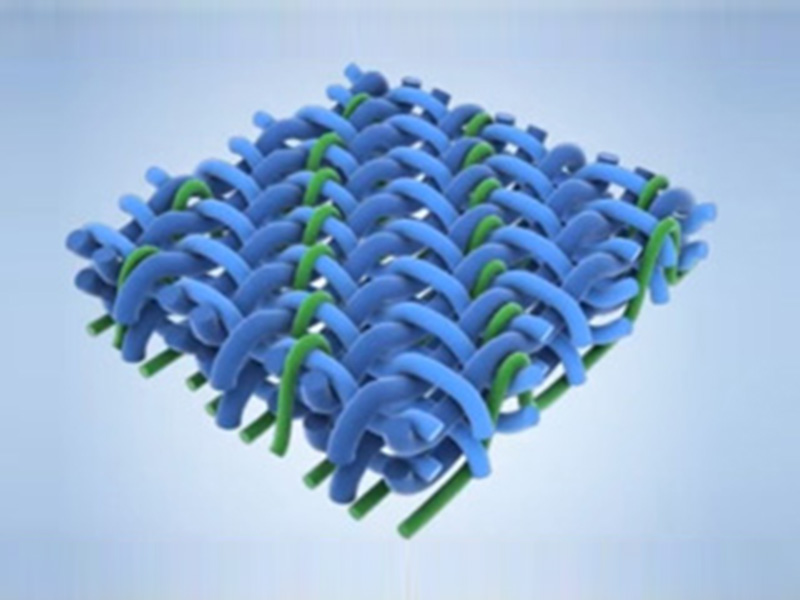

Two and a half layers forming fabrics– The double-layer forming fabrics has a flaw of the poor balance of the dehydration efficiency and fiber support, so two-layer and half come out.

The design of the 2.5 layer forming fabrics fully accounts for the higher degree of fiber retention without losing its dewatering properties, this design has a higher fiber support index than a double-layer wire design, which is achieved by adding additional transverse braiding lines on top of the double-layer polyester mesh, this greatly reduces the distance between the top line and the line and provides better support for fine fibers.

The 8-shed 2.5 layer forming fabric is the most common 2.5 layer polyester forming mesh. its weaving effect greatly increases the fiber support index due to the addition of a fine weave at the top. The ratio of the top and bottom wefts is 2:1.

The 8-shed above and 16-shed below weaving technology, its performance greatly improves the surface smoothness and higher paper support effect.

1.Good top layer smoothness;

2.Excellent formation and excellent fiber support;

3.No fabric marking and easy to clean;

4.Very good stable and wear resistance;

5.Good paper threading and retention.

Application

1.Paperboard.

2.Newsprint,writing paper.

3.Tissue paper.

4.printing paper,kraft paper.

Although the two and a half layer forming fabrics have good advantages, it is not unassailable, it does not maximize the characteristics of the upper and bottom layer due to structural limitations, so the triple-layer emerge on demand. Triple-layer forming fabrics– two single-layer forming fabrics bound together by a set of smaller CD strands, to get much better-supporting points. The surface layer is flat heald which has the better property for sheet forming, the bottom layer in four, five or six healds to get good wear resistance.

The Triple-layer forming fabrics has congenital insufficiency. First, the upper layer and the bottom layer are easily dislocated due to the force or damage of the connecting line or even “divided” and scrapped. Second, the bonding line has a negative effect on both forming and dehydration. In order to overcome these shortcomings, we have the self-supported binder (SSB) forming fabrics. The SSB structure utilizes the upper weft yarn to combine the bottom layer directly, without the additional binding yarns, which comprehensively maintains the advantages while overcoming the deficiencies of the three-layer fabrics.

The triple layer forming fabrics main used in the forming part of paper machine, Our three-layer polyester forming mesh could let us better distinguish the weaving design between the machine side and the paper side of the fabric, and the upper are the same mesh number with lower layer,which results in excellent paper sheet surface and stable high life potential.

An important advantage of our three layer forming fabrics is low warp density,another anvantage of this types: the weft wire of the wear surface spans a lot, that could gives the polyester forming fabrics a long life postential,the weft span would be 8 warp rather than common 6 or 5 warp, choosing the best polyester forming mesh type will save many costs in terms of clean operation, additive use, and vacuum, water, and electricity consumption.

1.For paper and board grades that require excellent printability.

2.Excellent formation and excellent fiber support.

3.No fabric marking and easy to clean.

4.Very good stable and wear resistance.

Application

1.Cigarette tissue,cigarette finer tissue,copy tissue,LC,LWC.

2.Newsprint,writing paper,carbonless paper,copper print.

3.Tissue napkin,tolite tissue.

4.Top or liner side for kraft and card board.

To avoid the blemish on the paper sheet, the most important requirement of monofilament is uniformity diameter over the entire length of the yarn.

High tenacity polyester (PET) monofilament yarns are used in the warp (MD) to provide the required high tension of the forming fabrics, and the diameter of MD yarn usually between 0.12 to 0.30 mm.

The monofilament yarn in the weft (CD) of the paper side is usually 100% polyester in high density to get better fiber support, while the mechanical (bottom) layer is composed of 50% polyester and 50% nylon in thicker diameter to ensure better wear resistance property. Nylon monofilament provides good abrasion resistance, but it’s not stable in hydrolyzed as PET under humidity conditions, so it will not exceed 50% typically. The diameter of the weft (CD) yarn is usually between 0.11 and 0.45 mm.

A properly designed constructed and maintained forming fabrics will help the former produce a sheet that meets end-products specifications at an acceptable production rate. The variables design and construction of paper machine forming fabrics influence overall sheet quality. The main property of Forming fabrics is as follows:

Dehydrate property, expressed parameter by air permeability and Drainage Index (DI). The pulp concentration is roughly 0.4%~1%, that is, more than 99% of the pulp is water, and about 96% of the water is dewatered in the forming section. The forming fabric has to dehydrate a huge volume of water in a short span of time.

Fiber support capacity: expressed by the Coefficient of Fiber Support(FSI). Good forming fabrics not only need to drain the water rapidly but also have to support the fibers on the surface to form a sheet. Good fiber support of the forming fabric improves the sheet characteristics such as flatness, smoothness, printability and strength properties, also avoids fiber embedding or clogging of the forming fabric, reduce the loss of fine fibers and fillers.

Mechanical property: The mechanical property of a forming fabric includes:

a.The transmission ability to transfer the sheet to the press section on the paper machine, and the ability to guide and drive the forming fabric itself.

b. Stability in lateral to ensure good sheet flatness of the side part, and stability in longitudinal to enhance efficiency and running property.

c.Good stiffness which will increase the transfer capacity of the paper machine and efficiency.

d.Excellent wear resistance make the forming fabric to be long service life.

The running property of the forming fabrics and the quality of the formed sheet depend on the retention rate and forming of the fiber. Taifeng'spaper machine clothing has the features of below:

l Good and properly designed woven structure, excellent drainage efficiency and fiber support, easy clean and maintain.

l Made out by the top quality of raw material, which has even yarn diameter, good strength and wear resistance property and longer service lifetime.

l Woven by Texo looms to achieve a highly precise and smooth surface.

l Max. width 13.5M.

l Bonfilt have a complete portfolio of the paper machine clothing, the single to triple layer of forming fabrics.

l Endless seam by automatic seaming machine, no-marking and has nearly the same property as the fabric surface.

l Heat setting by Juergens oil roller heat setting machine to anti-deforming and better dimensional stability, low elongation, smooth running performance.

l The formed sheet has a non-marking surface, high acceptable rate.

For Business: For Business inquiry fill our feedback form and Troll Free Number +86 15130825795, our team will help you with in 24 hours.

Company