Polyester Spiral Press-Filter Fabrics

Polyester Spiral Press-Filter Fabrics Description

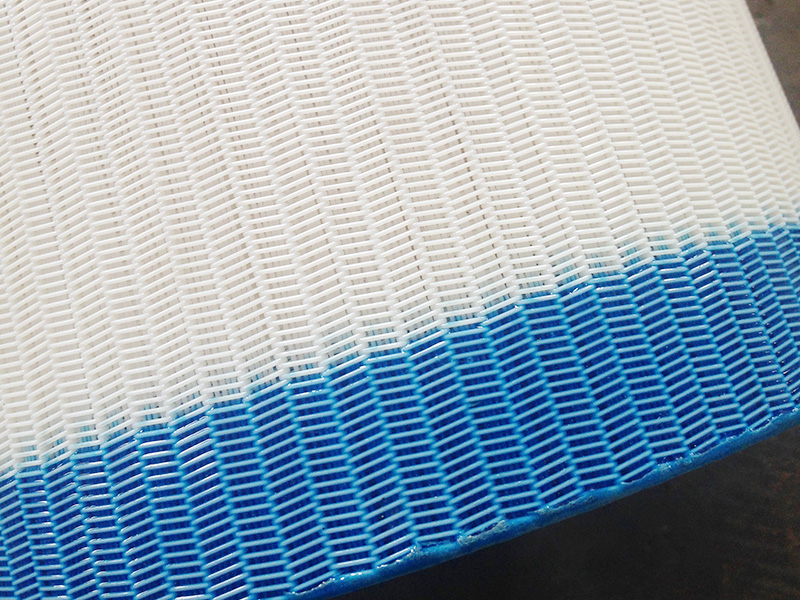

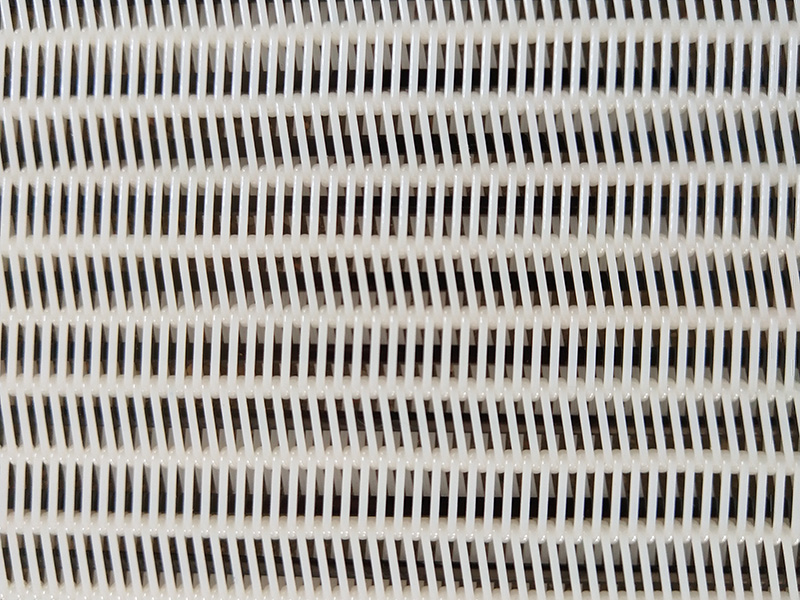

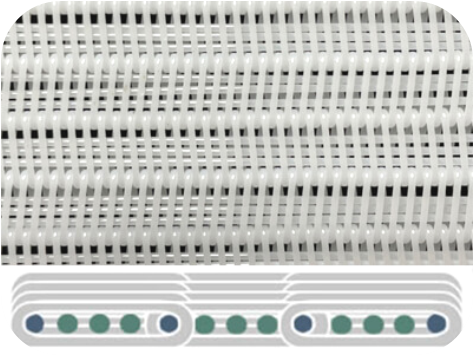

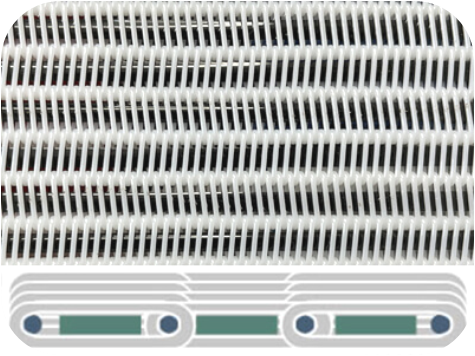

Polyester Spiral Press Filter Belts are made with spiral dryer fabrics with extra filler yarns inserted in the spiral loops to reduce the air permeability and less material loss on the surface of the fabric.

Polyester Spiral Press Filter Belt is also a monofilament polyester fabric but not like a woven fabric, instead this is a polyester fabric with spiral twisted wires where pins hold the spirals together like a chain.

For years we have been manufacturing filter belts made of synthetic fabrics for a wide range of pressure belt filters of different sizes and designs, applicable for dewatering or solid-liquid separation in industries such as mining, chemical, food or wastewater treatment.

Spiral Press Filter Belt with Round Inserting Bars

Spiral Press Filter Belt with Flat Inserting Bars

Feature

● The Polyester Spiral Press Filter Belts are produced with high cross-sectional stability and long service life.

● The Polyester Spiral Press Filter Belts width can be from 20 to 500 cm, depending on the filtration equipment.

● Due to the special structure of the spiral ring, there can be no seams at the filter belt connection

● Robust glued edges

Application

Spiral fabric belts with filling yarns are mainly used as filter cloth, drying media or conveyor belts for solid-liquid separation in the belt press filter.

We supply a wide variety of belts for industrial filtration or for environmental applications, choosing the material according to the characteristics of the product to be filtered, the work pressure, temperature, etc. that allows achieving a perfect solid-liquid separation. The type of material for a belt can vary depending on the customer's specifications and applications.

● Solid-liquid separation & drying

● Effluent treatment (wastewater, sewage,

sludge de-watering)

● Pharmaceutical & chemical industry

● Mining & mineral industry

● Pulp & paper industry

● Food industry

Polyester Spiral Press-Filter Fabrics for sldge dewatering

Polyester Spiral Press-Filter Fabrics for Meltblown cloth

| Type | Spiral loop width | Filament diameter | Strength | Weight | Thickness | Air permeability | CFM | ||

| (mm) | (mm) | (N/cm) | (Kg/m2) | (mm) | (m3/m2h) | (127/pa) | |||

Spiral ring monofilament | Connectio Wire | filler material monofilament | |||||||

| Small loop 5080A1 | 5.2 | 0.5 | 0.8 | 0.60*3 | 1800 | 1.5 | 2.1 | 4480 | 280 |

| Medium loop 6890A1 | 8 | 0.68 | 0.9 | 0.80*4 | 2000 | 2 | 2.45 | 6080 | 380 |

| Medium loop 6890B1 | 7.15 | 0.68 | 0.9 | 0.90*3 | 2000 | 1.9 | 2.45 | 5760 | 360 |

| Medium loop 6890B2 | 7.15 | 0.68 | 0.9 | 0.80*3 | 2000 | 1.85 | 2.45 | 7750 | 484 |

| Medium loop 6890B3 | 7.15 | 0.68 | 0.9 | Flat Wire 2.1*0.80 | 2000 | 1.8 | 2.45 | 9000 | 563 |

| Medium loop 6890B4 | 7.15 | 0.68 | 0.9 | Flat Wire 2.1*0.88 | 2000 | 1.85 | 2.45 | 8000 | 500 |

| Medium loop 6890B5 | 7.15 | 0.68 | 0.9 | Conductive carbon wire | 2000 | 1.6 | 2.45 | 10000 | 625 |

| Large loop 9090A1 | 8 | 0.9 | 0.9 | 0.90*3 | 2300 | 2.3 | 3.03 | 7500 | 468 |

| Large loop 90110A1 | 10 | 0.9 | 1.1 | 1.0*4 | 2000 | 2.4 | 3.15 | 6240 | 390 |

| Alkali resistance PA90110A2 | 10 | 0.9 | 1.1 | 1.2*3 | 2000 | 2.25 | 3.15 | 6240 | 390 |

| Large loop 10090A1 | 8 | 1 | 0.9 | 1.0*3 | 2000 | 2.5 | 3.6 | 5000 | 315 |

| Large loop 120130A1 | 1.2 | 1.2 | 1.3 | 1.2*3 | 2600 | 2.85 | 4.3 | 7500 | 468 |

For Business: For Business inquiry fill our feedback form and Troll Free Number +86 15130825795, our team will help you with in 24 hours.

Company