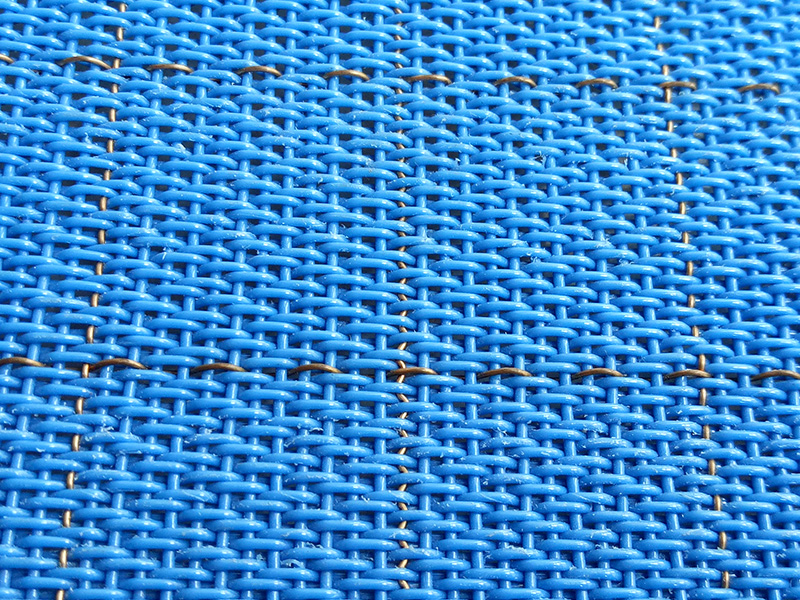

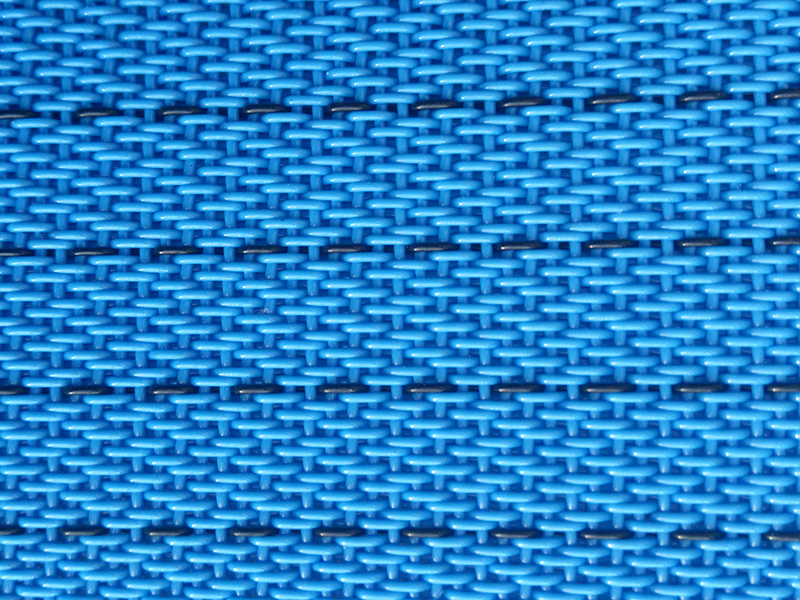

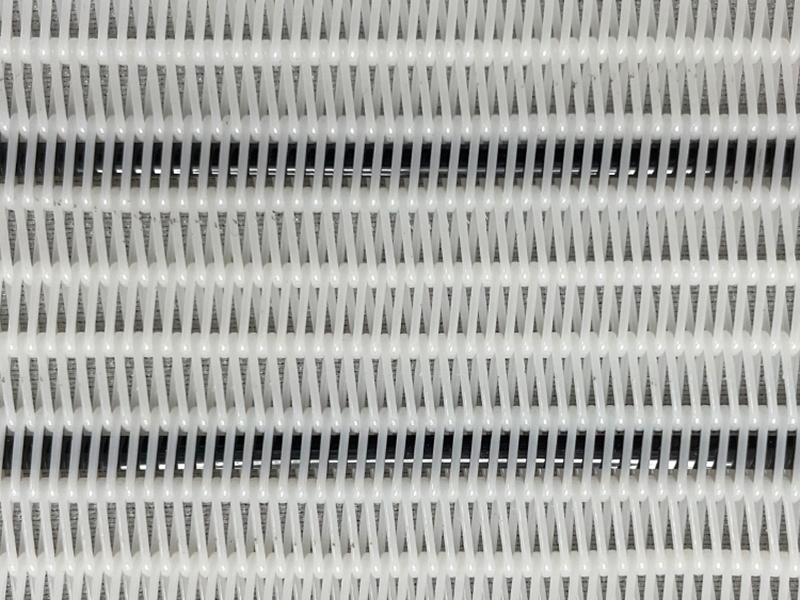

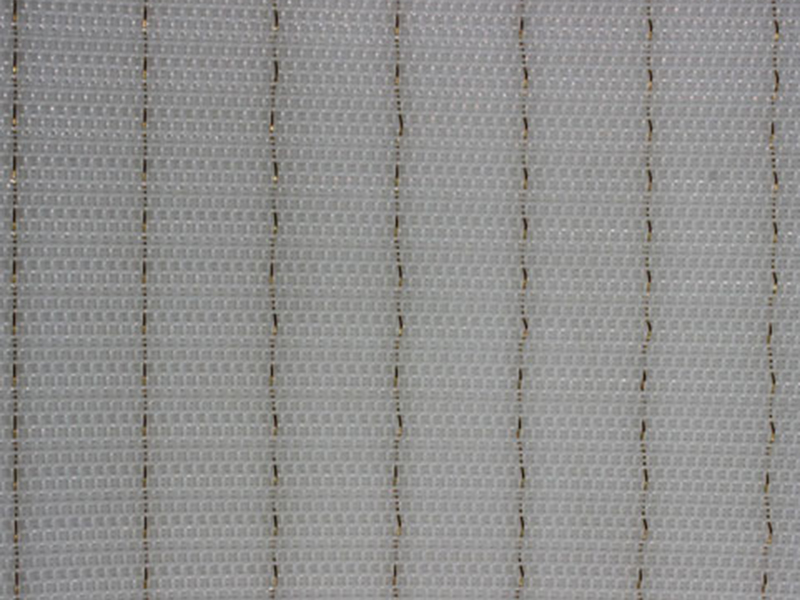

Polyester Anti-static Mesh Belts

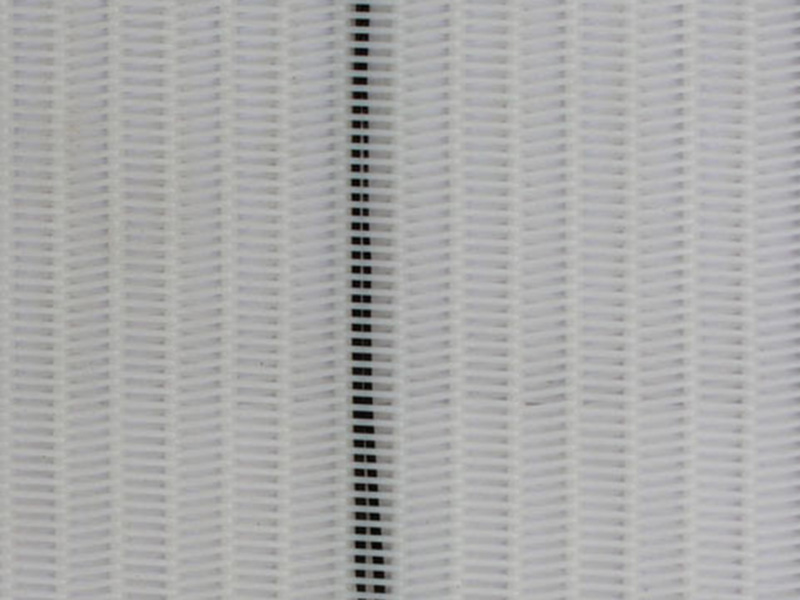

Anti-static principle

The polyester anti-static fabric is liable to generate friction electrostatic when the equipment is running at high speed. There is a conductive fiber through the polyester anti-static fabrics which can release the friction electrostatic, thus play a role on anti-static.

Although the static current is usually of low intensity, it can be the cause of problems like when light pieces of product stay adhered to the surface of the belt which reduces the efficiency and product quality, or combustion risk in environments sensitive to deflagration.

Polyester anti-static fabrics are mainly used in environmental protection, high density board making, rubber and chemical industry.

The accumulation of electrostatic charges can be dangerous for different reasons:

● There is a risk of fire and explosion in an environment with a large number of combustible materials.

● Produce radio interference, which may cause damage to electrical equipment.

● Workers are at risk of electrical injury when they touch the conveyor belt or something being conveyed.

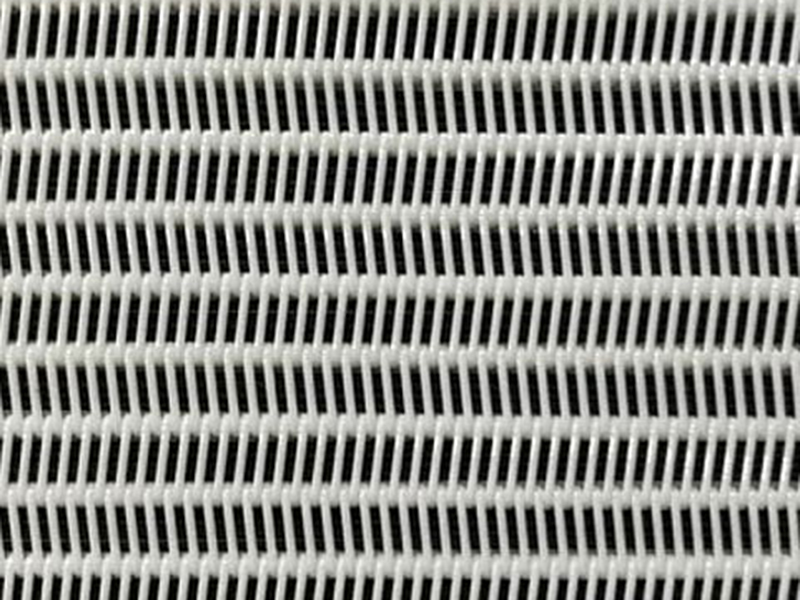

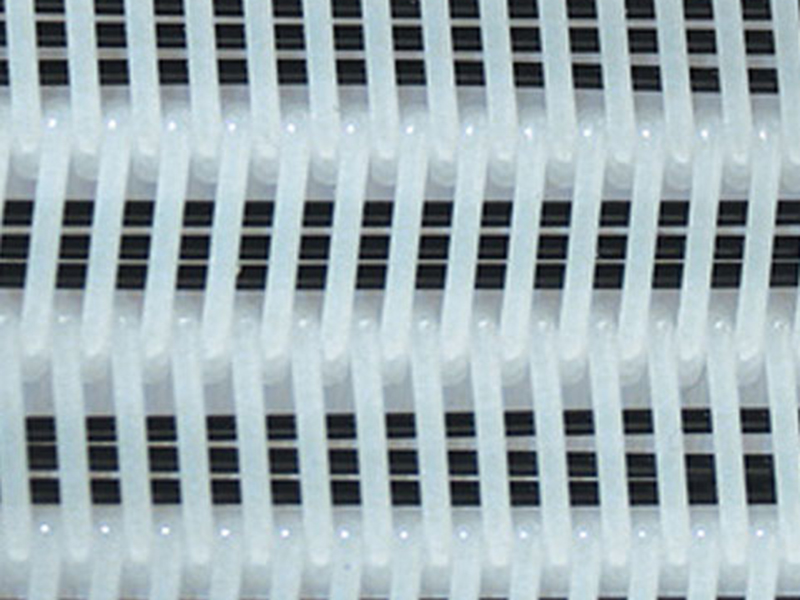

In order to solve these potential hazards, Taifeng Polyester Screen designed these antistatic mesh conductive belts to drive and dissipate surface static electricity accumulate during operation. The antistatic mesh conductive belts are woven from polyester monofilament and carbon or copper wire with good conductivity. There is a conductive fiber through the polyester anti-static fabrics which can release the friction electrostatic, thus play a role in anti-static.

Application

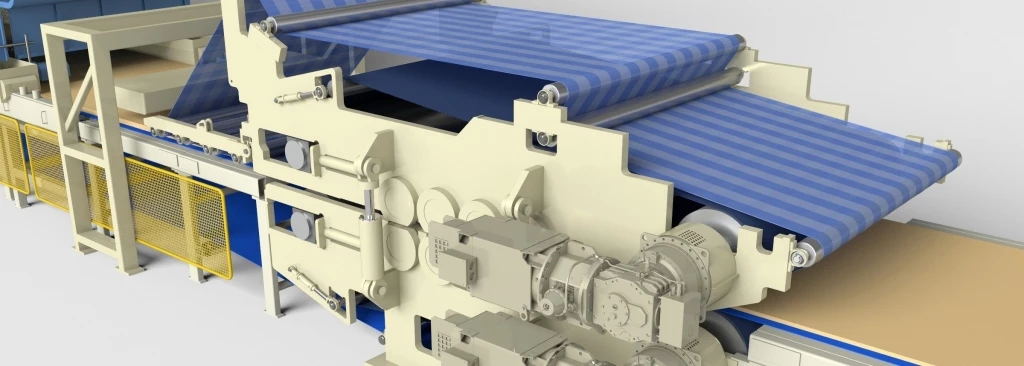

● Antistatic mesh belt is widely used in airlaid, spunlaid, wetlaid & drylaid nonwoven forming, wood fiberboard, dust-free paper, chemical fiber, and other industries.

● Used as continuous pre-pressing mesh belt in chemical fiber, pulp dry papermaking, fiberboard, and other industries.

● In applications, such as spunbond, meltblown, card and wetlaid nonwovens, the conductive fiber ensures reliable electrostatic discharge.

● Characteristic of antistatic mesh belt can also be used in environmental protection, rubber, chemical industry and other anti-static industries.

| Model of Conductive Conveyor Belts | Wire diameter | Density | Strength | Permeability | ||

| (mm) | (wire/centimeter) | (N/cm) | (m³/㎡h) | |||

| Warp | Weft | Warp | Weft | Area of the surface | ||

| 14804/anti-static | 0.65 | 0.8 | 14.8 | 7.2 | ≥2000 | 6800±500 |

| 14804-1/anti-static | 0.65 | 0.8 | 14.8 | 7.2 | ≥2000 | 15840±500 |

| 14708/anti-static | 0.64 | 0.7 | 15 | 8 | ≥2000 | 11200±500 |

| 12708/anti-static | 0.46x0.68 | 0.7 | 14.1 | 7.3 | ≥2000 | 8000±500 |

| 4106/anti-static | 0.5 | 0.5 | 23 | 12.6 | ≥2200 | 6800±500 |

| 3868/anti-static | 0.7 | 0.9 | N/M | ≥2000 | 17000±500 | |

| 4080/anti-static | 0.9 | 1.1 | N/M | ≥2300 | 20000±500 | |

For Business: For Business inquiry fill our feedback form and Troll Free Number +86 15130825795, our team will help you with in 24 hours.

Company