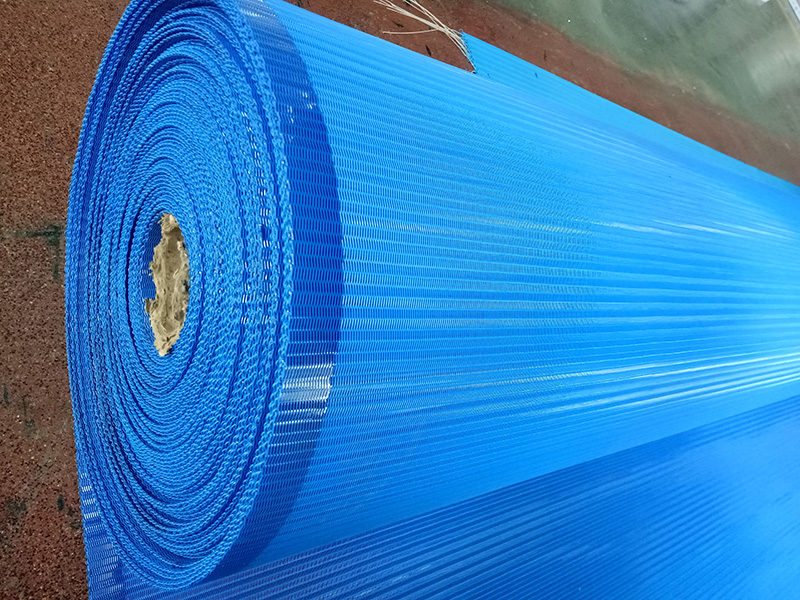

Polyester Spiral Dryer Screen / Fabric / Canvas are suitable for drying packing paper, cultural paper, board paper and pulp board which be requested with big quantity. The fabric is widely used in paper making, mining, food, pharmaceutical, printing and dyeing, rubber industry. Also could be used as conveyor belt and the laminating machine matching belt.

Polyester Spiral Dryer Screen have the advantage of larger air permeability, flat surface, good strength, long working time and joining or not arbitrarily.

Spiral dryer fabric description

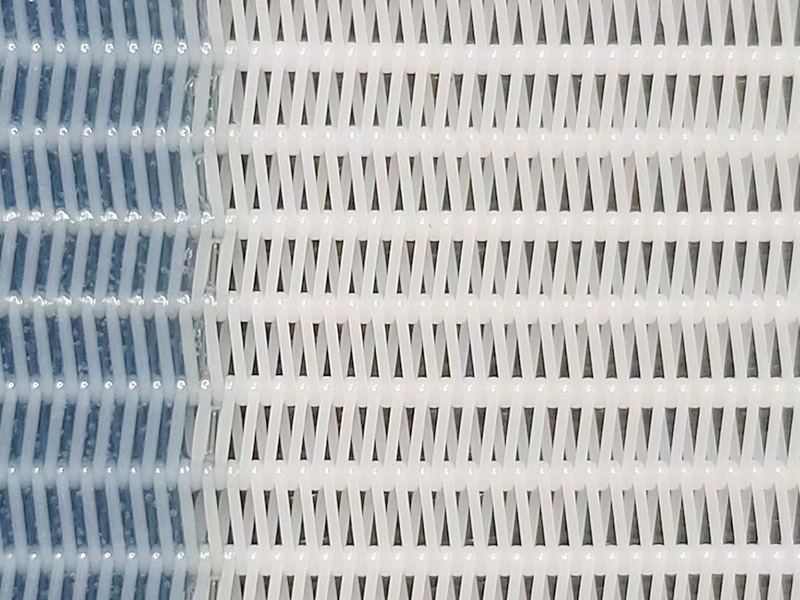

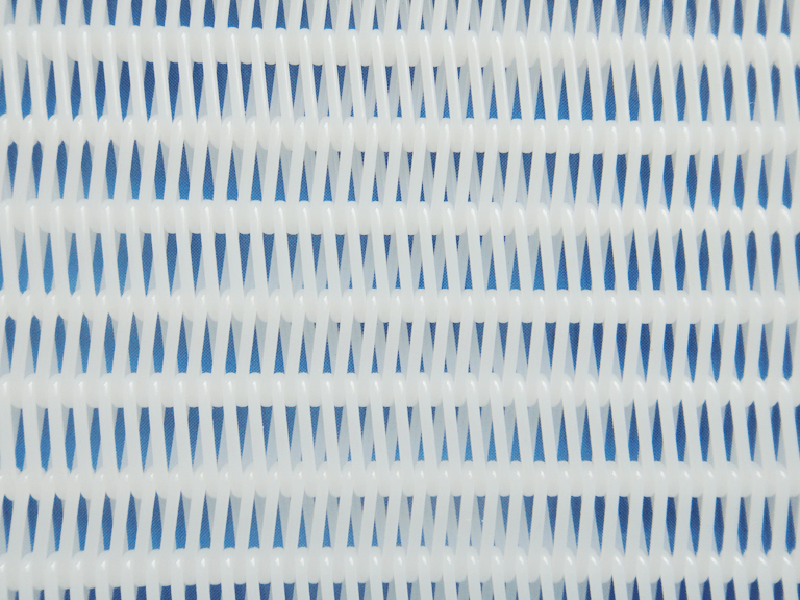

Spiral dryer fabric or screen is an endless construction comprising a plurality of spiral loops of monofilament yarns. The spiral loops linked by a pin yarn inserted in the adjacent holes.

The specially designed spiral structure allows for rapid drainage, superb distortion resistance and eliminates the need for conventional seams compared with the woven polyester dryer fabric.

According to your requirements, polyester spiral dryer fabric can be fabricated with round yarns or flat yarns. In contrast, the flat yarn spiral dryer is recommended to be used in high-speed paper drying machines owing to its smoother surface, better wear resistance, later contacting area, most of all, improved paper drying performance.

Spiral Dryer Fabrics is a medium to high permeability Spiral Dryer Fabrics used in conventional locations. It is made of hydrolysis and abrasion resistant PET, but its edges cannot be reinforced by PPS yarn. Their air permeability ranges from 150 to 900 CFM, depending on the type of filler wire inserted in the spiral. The seam consists of spirals of the same quality and strength as the dry net. Spiral Dryer Fabrics are suitable for drying locations where joint damage usually occurs. They have high diagonal stability and a relatively uniform distribution of tension and air permeability, even when deformed.

| Types of Spiral Dryer Fabric | Spiral loop width | Thread Diameter | Tensile strength | Weight | Thickness | Air Permeability | CFM | |

| (mm) | (mm) | (N/cm) | (kg/m2) | (mm) | (m3/m2h) | (127/pa) | ||

| warp | weft | |||||||

| Small loop 5080A | 5.2 | 0.5 | 0.9 | 1800 | 1 | 2.1 | 15000 | 9375 |

| Medium loop 6890A | 8 | 0.68 | 0.9 | 2000 | 1.31 | 2.45 | 18000 | 11250 |

| Medium loop 6890B | 7.15 | 0.68 | 0.9 | 2000 | 1.4 | 2.45 | 16000 | 10000 |

| Medium loop 9090A | 8 | 0.9 | 0.9 | 2300 | 1.8 | 3.03 | 19000 | 11875 |

| PPS9090B | 6.48 | 0.9 | 0.9 | 2000 | 1.9 | 3.3 | 14000 | 8750 |

| High-temperature resistance 250 ℃ | ||||||||

| PPS9090C | 8.3 | 0.9 | 0.9 | 2000 | 1.74 | 3.5 | 19000 | 11875 |

| High-temperature resistance 250 ℃ | ||||||||

| Large loop 90110A | 10 | 0.9 | 1.1 | 2300 | 1.65 | 3.15 | 20000 | 12500 |

| Large loop 10090A | 8 | 1 | 0.9 | 2000 | 2 | 3.6 | 17000 | 10625 |

| Large loop 120130A | 12 | 1.2 | 1.3 | 2600 | 2.35 | 4.3 | 22000 | 13750 |

Feature

Spiral dryer fabric feature

Spiral dryer fabric has a specially designed spiral structure that allows for rapid drainage, superb distortion resistance and eliminates the need for conventional seams compared with the woven polyester dryer fabric. Meanwhile, it allows the filtered cakes to be removed quickly.

Spiral dryer fabric must be heat resistant, rugged, and designed for both dryings efficiently and evenly. Each Spiral dryer fabric is produced only client-specific in order to meet the exact specifications of each machine position.

● Spiral dryer fabric is available in a broad air permeability range.

● Spiral dryer fabrics are easy to fit and install, simple to clean and remain stable even after long-running times of operation.

● Max air permeability and high wear resistance.

● Excellent dimensional stability of Spiral Dryer Fabrics

● Spiral Dryer Fabrics excellent abrasion resistance and durability

● Spiral Dryer Fabrics have no seam markings or premature wear

● Spiral Dryer Fabrics can add ventilation holes to improve drying/reduce energy costs

● Spiral Dryer Fabrics have greater permeability and drying efficiency

● Spiral Dryer Fabrics are high temperature hydrolysis resistant yarns

● Spiral Dryer Fabrics have good tensile strength

Application

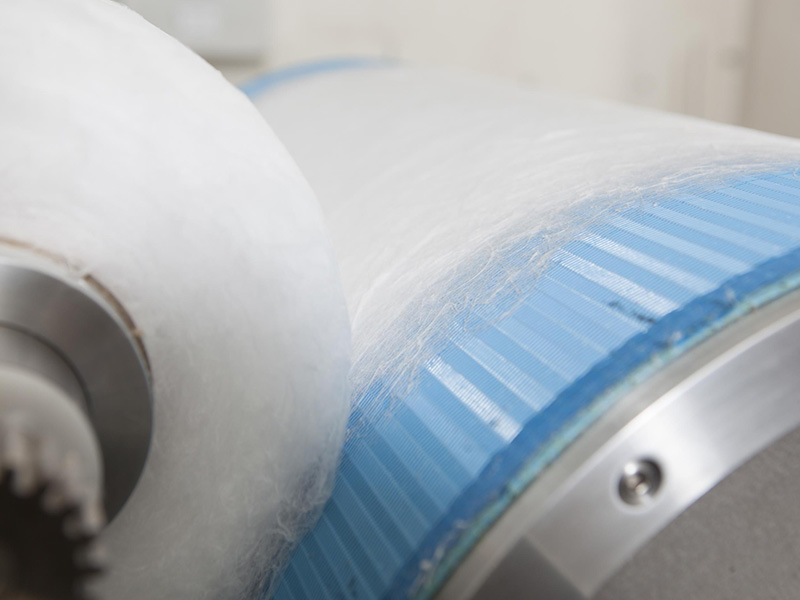

Dryer screen dries paper web after passing a press section by adhering the web to a steam-heated cylinder. In the dryer section of the paper machine, the paper sheet travels around large-diameter heated cylinders, remaining water is removed by evaporation. Spiral dryer fabrics are widely used in various industries as papermaking dryer fabrics, filter mesh belts, or dryer conveyor belts.

Spiral Dryer Fabrics are widely used in many other industries such as food drying, non-woven conveying, printing textile drying and so on.

Spiral Dryer Fabrics belt is mainly used for multi-cylinder fourdrinier paper machine and multi-cylinder cylinder machine, suitable for all kinds of board paper, corrugated paper, kraft paper, bag paper, tube paper, linoleum base paper, train ticket paper, thick board paper, pulp board Paper and heavy-duty writing paper and wrapping paper.

Since the advent of the vacuum washer, Spiral Dryer Fabrics have become a special filter fabric.

Spiral Dryer Fabrics are also used in rotary screen printing machines in the printing and dyeing industry, coal washing machines in the coal washing industry, oven conveyor belts in the food processing industry, etc., to obtain the best performance.

Polyester Spiral dryer fabrics for Paper making machine

Polyester Spiral dryer fabrics for Meltblown cloth

For Business: For Business inquiry fill our feedback form and Troll Free Number +86 15130825795, our team will help you with in 24 hours.

Company